- Home

- About Us

- Products

- Shop

- Equipment

- Recycling

- Vacuum System

- Brochures

- Contact Us

- Cart

- My Account

PROFESSIONAL SERIES

Features

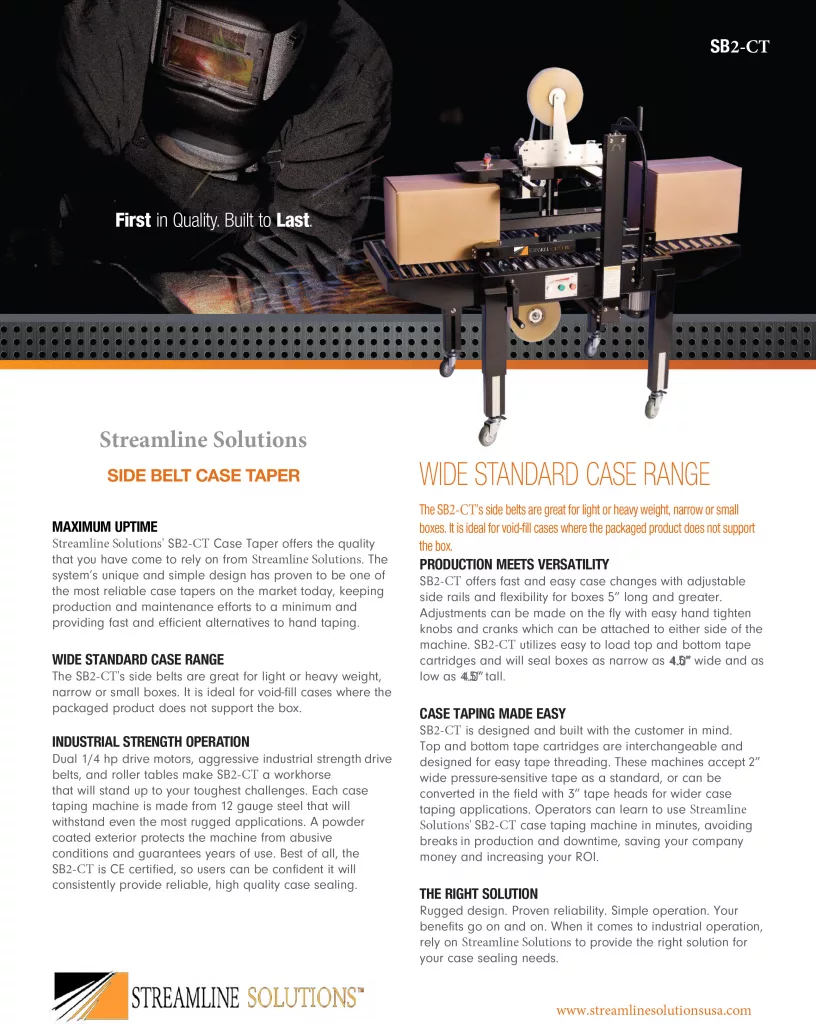

SIDE BELT CASE TAPER

Streamline Solutions’ SB2-CT Case Taper offers the quality that you have come to rely on from Streamline Solutions. The system’s unique and simple design has proven to be one of the most reliable case tapers on the market today, keeping production and maintenance efforts to a minimum and providing fast and efficient alternatives to hand taping.

The SB2-CT’s side belts are great for light or heavy weight, narrow or small boxes. It is ideal for void-fill cases where the packaged product does not support the box.

Dual 1/4 hp drive motors, aggressive industrial strength drive belts, and roller tables make SB2-CT a workhorse that will stand up to your toughest challenges. Each case taping machine is made from 12 gauge steel that will withstand even the most rugged applications. A powder coated exterior protects the machine from abusive conditions and guarantees years of use. Best of all, the SB2-CT is CE certified, so users can be confident it will consistently provide reliable, high quality case sealing.

Taping Specs

- Sealer Type – Side belt, top and bottom case sealer

- Machinery Makeup – Industrial strength 12 gauge steel, powdered coated for durability

- Belt Speed – 75 feet/per minute

- Tape Speed – 30 cases/per minute, depending on box size and operator efficiency

- Height Adjustment – Standard adjustable legs for 18.1” to 32.3” conveyor heights

- Tape Size – 2” wide pressure sensitive tape, up to 15” diameter rolls, optional 3” wide tape

- Tape Cartridge – Proven design requires no lubrication, tips back for simple tape threading, removable for maintenance and interchangeable with top or bottom cartridges

- Drive Motor – Two (2) 1/4 HP drive motors

- Electrical Requirements – 110 VAC, 60Hz, 4.0A

- Agency Approvals – CE Certification

Box Specs

- Minimum Box Size – 5″ (Length) 4″ (Width) 4″ (Depth)

- Maximum Box Size – infinite (Length) 19.5″ (Width) 19.5″ (Depth)

Options

- 3” Tape Head – Accepts 3” wide tape rolls

- Stainless Finish – Complete stainless finish to meet specific application requirements

EQUIPMENT DESIGNED FOR SPEED & EFFICIENCY

WITH A PROFESSIONAL PRESENTATION

Top and bottom tape heads are interchangeable and tip back for easy threading.

Interchangeable Heads

Industrial strength roller beds move boxes consistently through the taper.

Industrial Rollers

Adjustable side rails and tape head offer fast and easy case changes

Adjustable Side Rails

Top and bottom tapeheads are identical and can be removed instantly without tools. Choose from two options