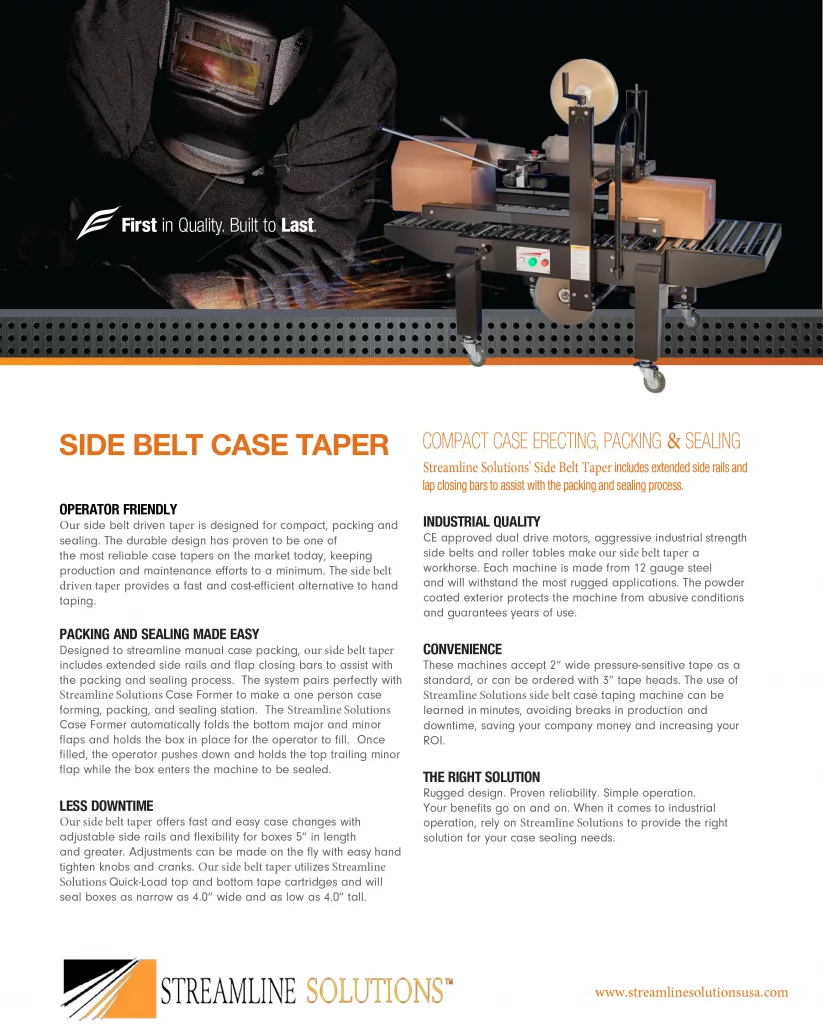

Our side belt taper is designed for compact, packing and sealing. The durable design has proven to be one of the most reliable case tapers on the market today, keeping production and maintenance efforts to a minimum. Our side belt taper provides a fast and cost-efficient alternative to hand taping.

Designed to streamline manual case packing, our side belt taper includes extended side rails and flap closing bars to assist with the packing and sealing process. The system pairs perfectly with Streamline Solutions’ Case Former to make a one person case forming, packing, and sealing station. The Streamline Solutions Case Former automatically folds the bottom major and minor flaps and holds the box in place for the operator to fill. Once filled, the operator pushes down and holds the top trailing minor flap while the box enters the machine to be sealed.

Our side belt taper offers fast and easy case changes with adjustable side rails and flexibility for boxes 5” in length and greater. Adjustments can be made on the fly with easy hand tighten knobs and cranks. Our side belt taper Quick-Load top and bottom tape cartridges and will seal boxes as narrow as 4.0” wide and as low as 4.0” tall.

CE approved dual drive motors, aggressive industrial strength side belts and roller tables make our side belt taper a workhorse. Each machine is made from 12 gauge steel and will withstand the most rugged applications. The powder coated exterior protects the machine from abusive conditions and guarantees years of use.

These machines accept 2” wide pressure-sensitive tape as a standard, or can be ordered with 3” tape heads. The use of Streamline Solutions’ case taping machine can be learned in minutes, avoiding breaks in production and downtime, saving your company money and increasing your ROI.

Rugged design. Proven reliability. Simple operation. Your benefits go on and on. When it comes to industrial operation, rely on Streamline Solutions to provide the right solution for your case sealing needs.