Magnetic control box mounting

Extrusion rail to easily mount ink jet printing systems and guide rails

Pre-drilled hole for encoder mounting

Shelf for various storage

Small space-saving footprint

Seamless self-tracking belt

¼” cold rolled steel

Variable speed drive

Optional guide rails available

Safety cover over pinch points

Smooth, consistent belt speed

- Home

- About Us

- Products

- Shop

- Equipment

- Recycling

- Vacuum System

- Brochures

- Contact Us

- Cart

- My Account

PROFESSIONAL SERIES

Features

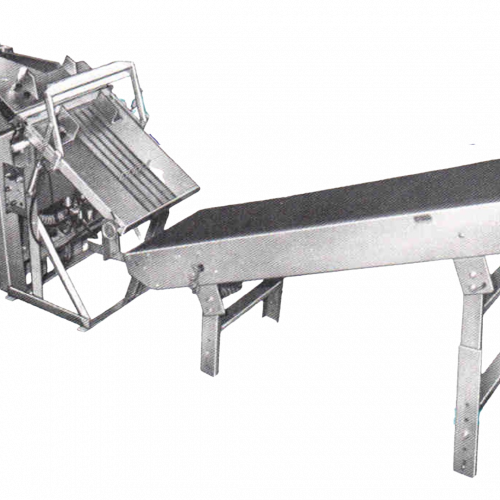

Variable Speed Conveyors

Streamline Solutions’ variable speed conveyors offer the quality that you have come to rely on from Streamline Solutions. The Streamline Solutions conveyors offer a reliable stand-alone product transport for primary or secondary product marking, and make a convenient add-on infeed or exit feed conveyor to existing case taping or shrink wrapping equipment.

Streamline Solutions’ conveyor design is perfect for integration with ink jet printing equipment. Each conveyor comes pre-drilled in multiple locations to easily add printer and encoder mounting brackets. The smooth drive belt provides consistent speed for reliable, scannable barcoding and product transfer. Systems include a lower shelf with holes for cable management and provide storage for supplies such as spare printheads, printer and UV LED control boxes, spare ink, and more.

Streamline Solutions conveyors utilize an endless belt with self-tracking V-groove for consistent alignment. The variable speed drive motor is adjustable up to 100 fpm for a variety of applications. The unit also features a magnetic control box that can be mounted on either side of the conveyor. Conveyor legs are adjustable from 20” up to 33.5”. The system is designed to keep maintenance to a minimum and provide a fast and efficient method of product transport.

Conveyor Specs

- Machinery Makeup – Industrial strength 12 gauge steel, powder coated for durability

- Variable Speed – Up to 100 fpm

- Conveyor Height Adjustment – legs and casters ordered separately:

- With 9” leveling legs: 20” – 33.5” (50.8cm – 85.1cm)

- With 9” legs and casters: 24” – 37.5” (61cm – 95.3cm)

- With 17” leveling legs: 28” – 41.5” (71.1cm – 105.4cm)

- With 17” legs and casters: 32” – 45.5” (81.2cm – 115.6cm)

- Electrical Requirements – 110V 5A Single Phase

- Max Weight Capacity

- SC1248, SC1848, SC2430 & SC2472 90 lbs. maximum weight

- SC1272, SC1872 100 lbs. maximum weight

Options

- Leveling Legs and Casters – Leveling legs and lockable casters for adjustable height and easy movement throughout the plant

- Additional Printhead Mounting Plate – Predrilled to mount full family of

- Streamline Solutions Printing Systems

- Guide Rails – Heavy-duty adjustable height and reach to align product for consistent print (sold separately per side)

- E-Stop – Large safety mechanism to shut off conveyor immediately

EQUIPMENT DESIGNED FOR SPEED & EFFICIENCY

WITH A PROFESSIONAL PRESENTATION

Single or dual optional side rails are available for box or primary product guidance.

Single or Dual Rails

Magnetic control box can be mounted on either side of conveyor.

Magnetic Control Box

Shelf included for storage such as spare print heads, printer and UV LED control boxes, spare ink, and more.

Storage Shelf

Included extrusion rail makes for easy for integration with ink jet printers and other equipment.