EQUIPMENT

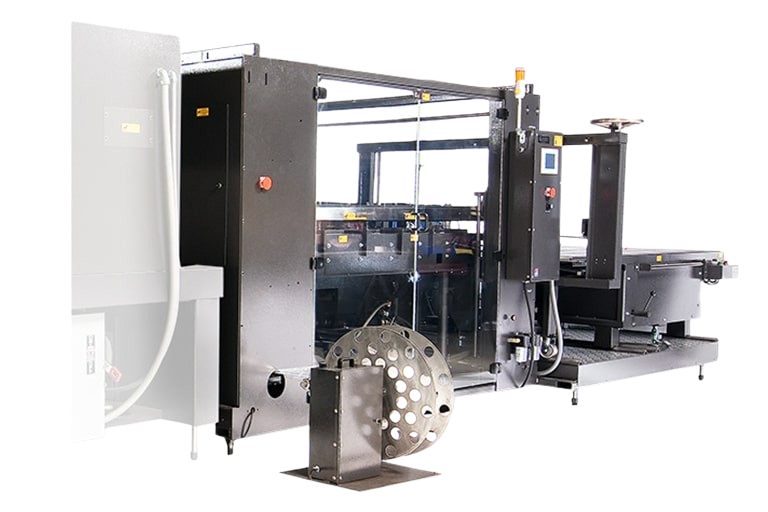

Streamline Solutions is proud to be able to offer the complete line of the highest quality L-Bar Sealers, Bundling Machines, Shrink Tunnels, Packaging Equipment, and Conveyers in the industry. The Streamline Solutions team will work with you to come up with the right equipment to meet your exact needs. We also do offer equipment parts as well.

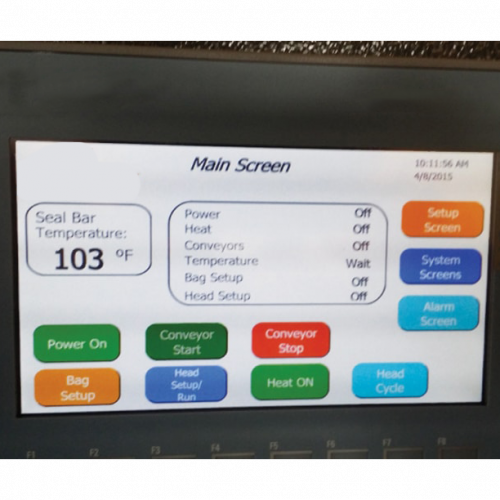

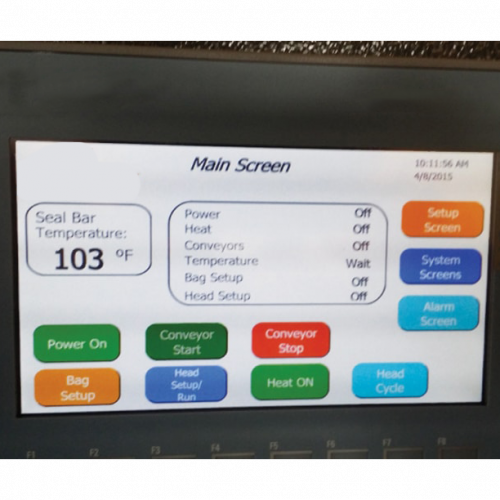

Color PLC touchscreen can be password protected if needed.

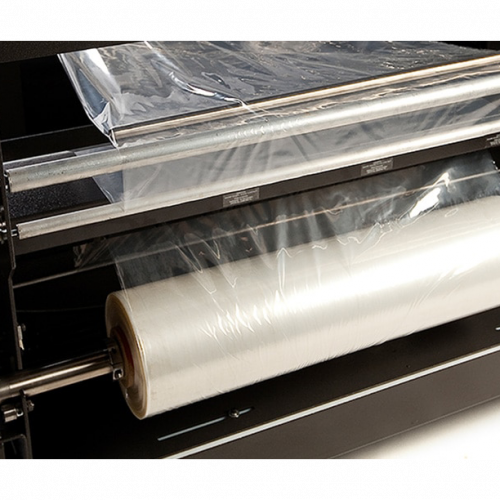

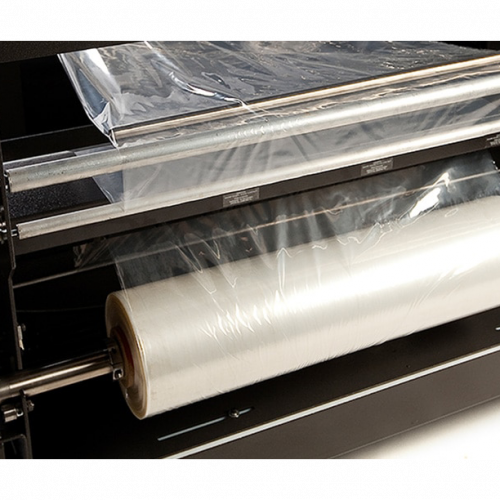

Power film unwind ensures proper tension of film.

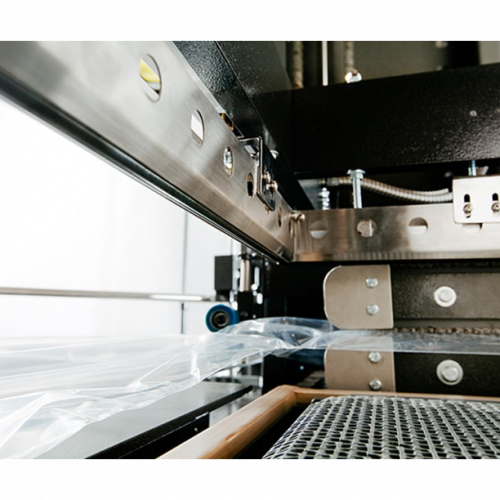

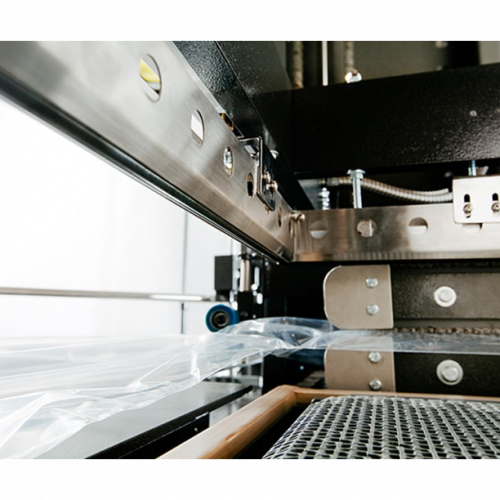

Hot knife seal system ensures a clean, positive, and even seal every time.

Easy to use control panel lets users adjust dwell time and temperature settings for their specific application.