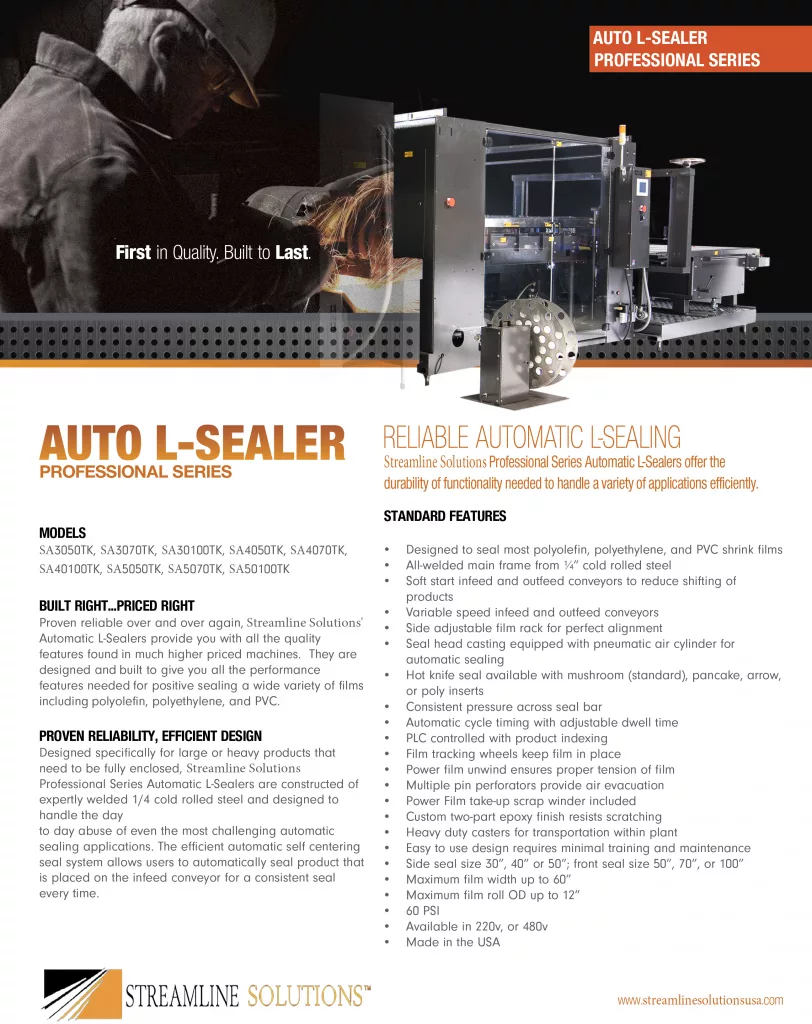

Proven reliable over and over again, these intermediate level Streamline Solutions Automatic L-Sealers provide you with all the quality features found in much higher priced machines. They are designed and built to give you all the performance features needed for positive sealing a wide variety of films including polyolefin, polyethylene, and PVC.

Designed specifically for entry-level or intermediate applications that require simple operation, small footprint, or a limited budget, Streamline Solutions’ Value-Series Automatic L-Sealers will handle the day to day abuse required for automatic sealing.