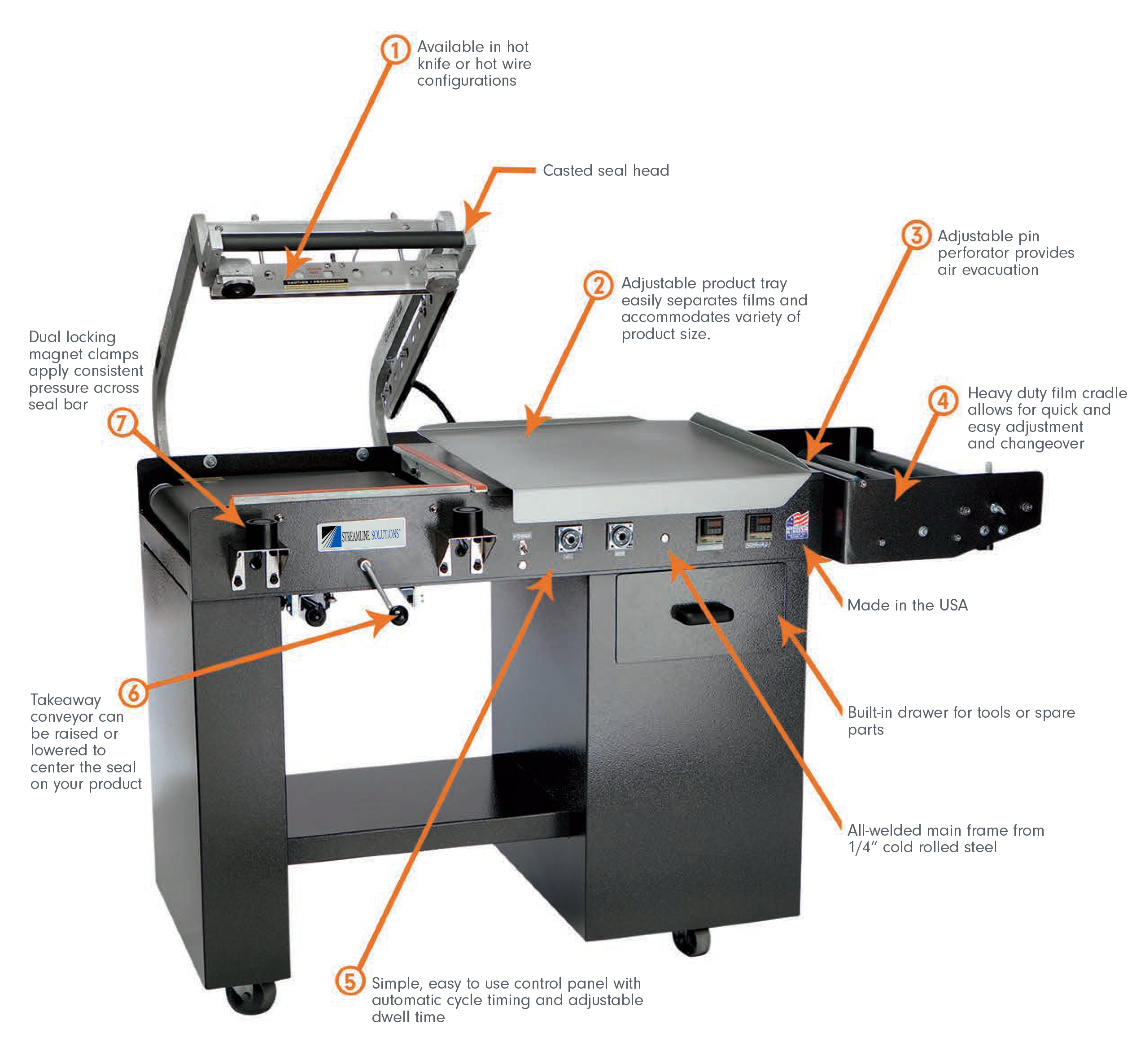

Professional Series L Bar Sealer

30″ x 40″ Professional Series L Bar Sealer

with Hot Knife Seal Head

Streamline Solutions‘ Professional Series L-Sealers provide top of the line features and the most robust L-Sealer design on the market today. Expertly welded from ¼” cold rolled steel, Streamline Solutions’ Professional L-Sealers will withstand even the most abusive real world sealing applications. As a measure of strength, Streamline Solutions L-Sealers weigh nearly twice as much as competitive models.

Call For Special Pricing (866) 244-7700!

SKU: SM3040

Categories: Centerfold Film, Equipment, Products

Tags: UFilm, LDPE, Low Density, Pallet Wrap, Shrink Film, Stretch Wrap, Poly, Centerfold, Centerfold Film, Polyethylene

Additional information

| Weight | 1300 lbs |

|---|---|

| Dimensions | 43 × 44 × 106 in |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.